The challenge

In power electronics, there are many applications where resistors are used. In inverters; for charging and discharging capacitor banks, filters, snubbers, drive systems, as brake resistors, and wind turbines as a Low-Voltage-Ride-Through energy dump resistor.

For charging and energy dump, resistors are not often in operation. They perhaps operate as little as one time per day. However, the braking system is in constant use in other applications such as an elevator or a similar lifting system, especially in rush hours.

The solution

With a power resistor, it all comes down to one aspect; temperature!

It is very easy; if the internal or external components become too hot, it will fail. We need to observe the resistor as a dynamic component with a dynamic power load. The energy that is generated in the resistor must be expelled to the outside. The ability to do this lies within the properties of the resistor itself.

Suppose we can establish a model that would show us where the energy is generated and how it can be expelled to the outside. In that case, we can simulate the different temperatures and determine whether the resistor is up to the job.

Thermal simulations

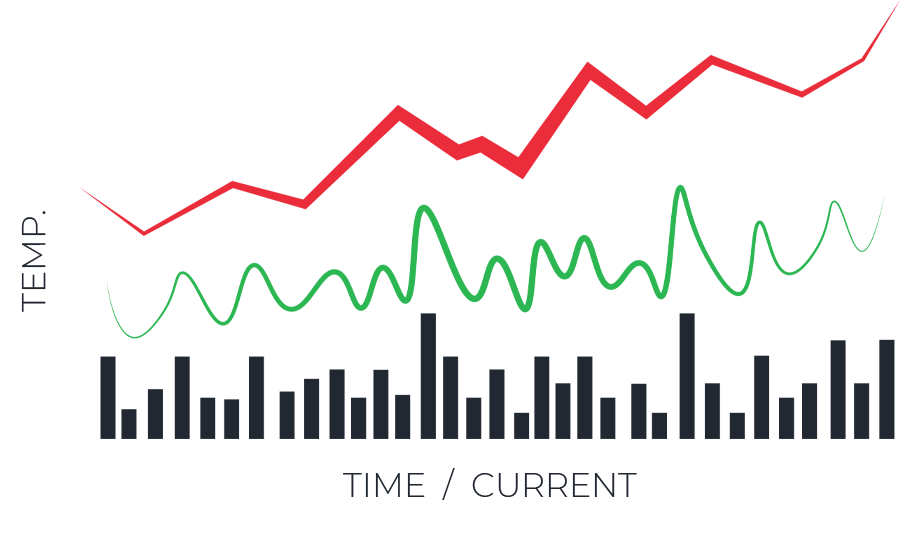

A simulation has three basics; the thermal model, the power load coming from the electrical circuit and the output. The power load comes from the application.

The internal temperature rise in the resistor and on the surface can be calculated by using a standard simulation software (e.g. P-Spice) for calculating an electric circuit. Danotherm provides specific individual models to customers for simulation. Alternatively, Danotherm offers to simulate with a customer specific load cycle.

The output is usually a scope plot. The thermal model has two or more points where the temperature can be measured; the internal active resistor wire and one or two housing or casing temperatures. If the temperatures are within physical and also within customer specified limits, the resistor is up to the job.

We have created thermal models for all ALPHA, OHMEGA and Ceramic resistor types.

A resistor is past the design stage at the time of manufacture.

Designing the right solution starts with having a clear idea of what you want to achieve. Design and selection of the power resistors require knowledge and experience. Our experienced engineers are able to guarantee the best performance from your device, as well as provide you with the highest quality product.