Power Range

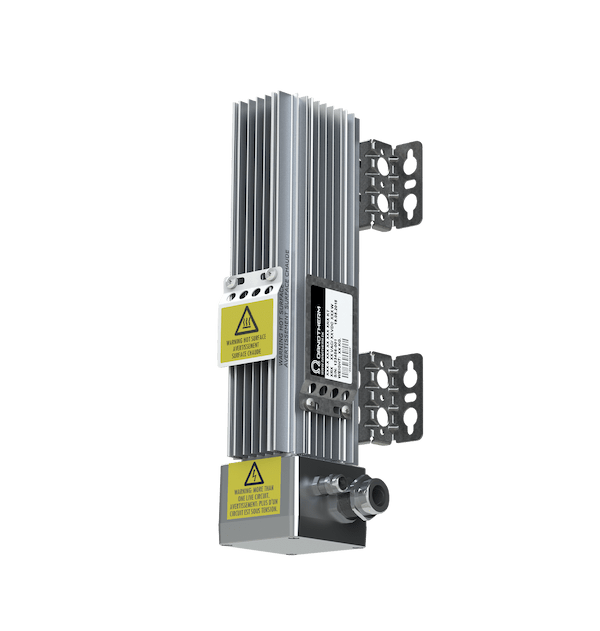

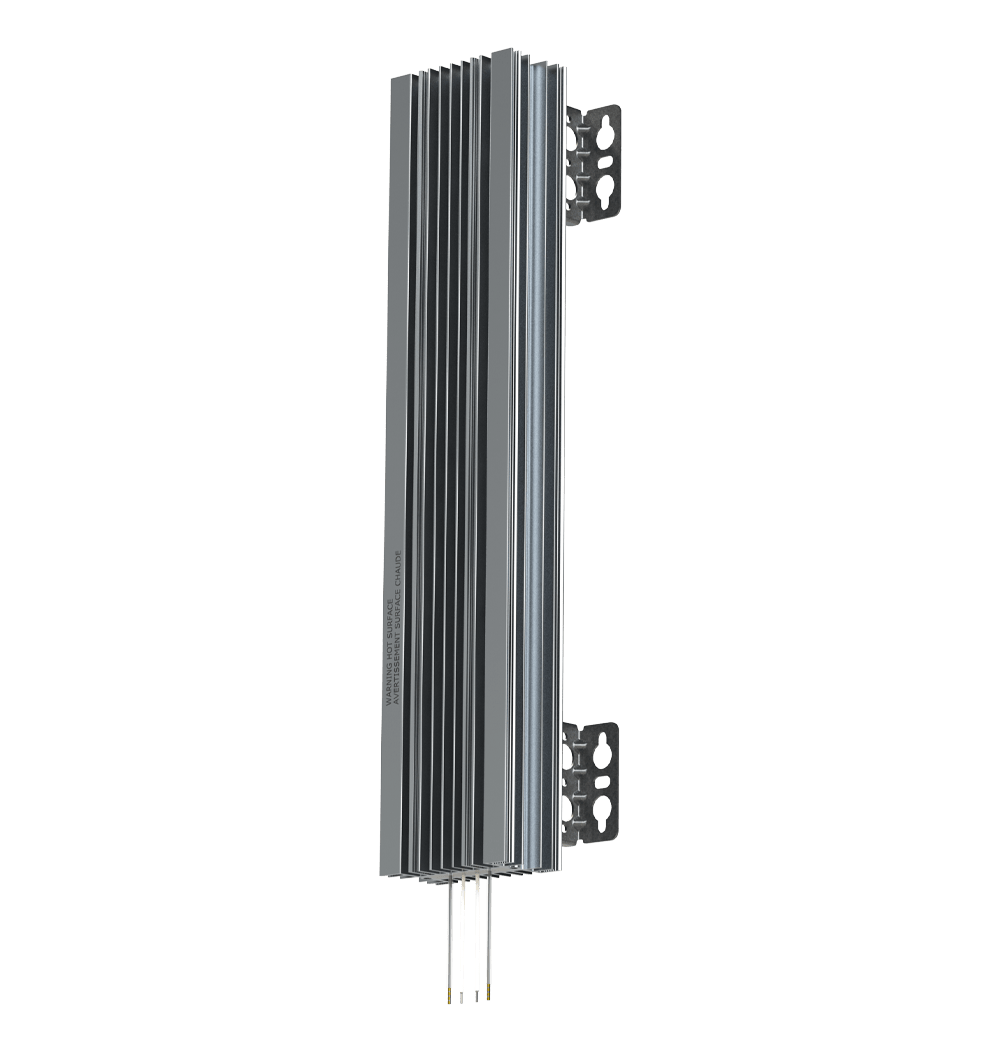

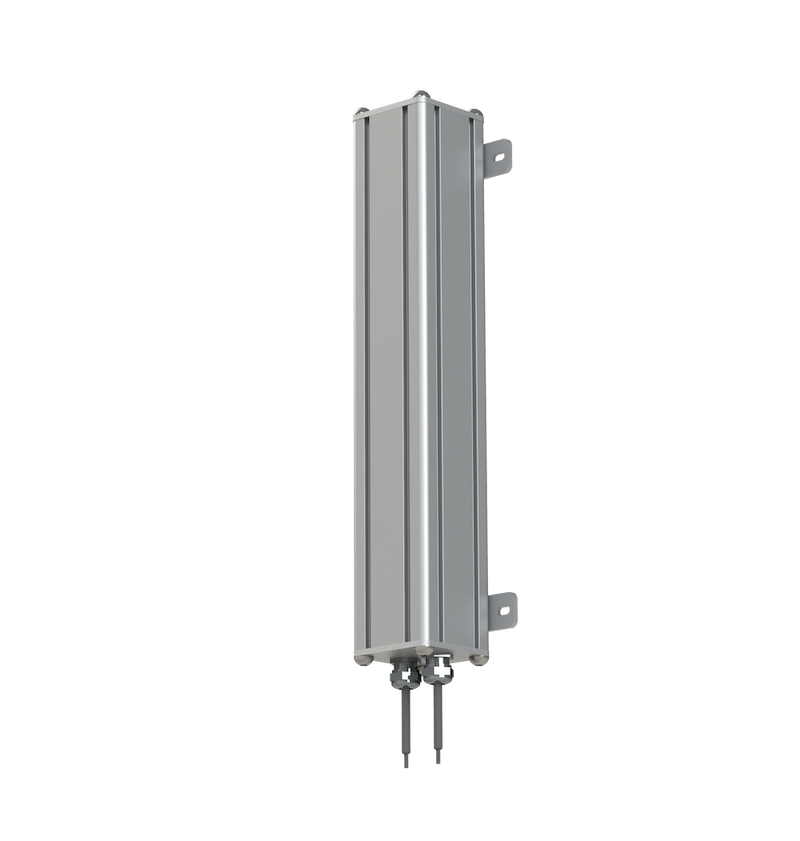

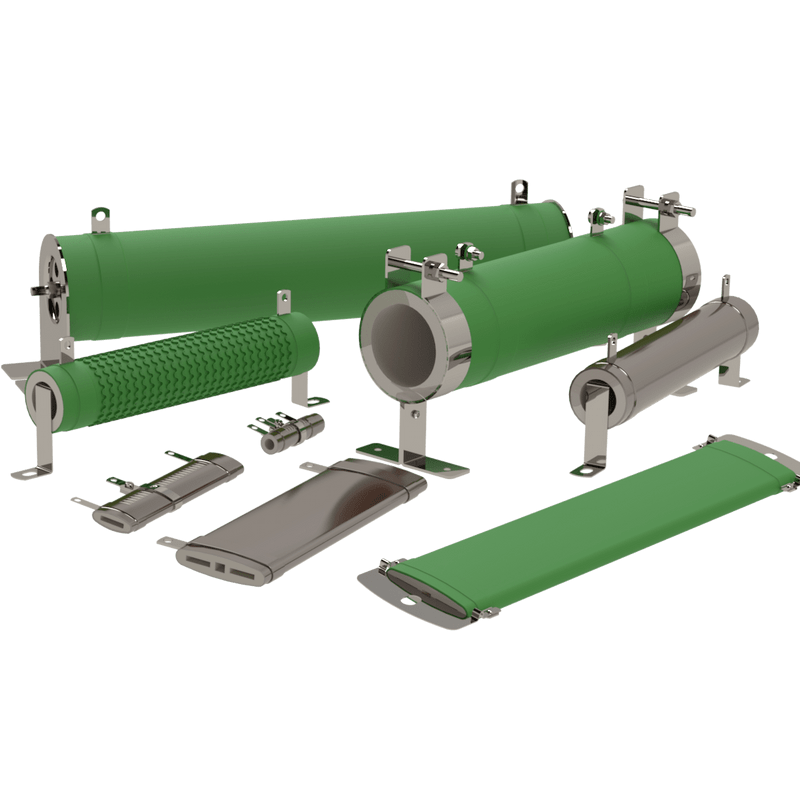

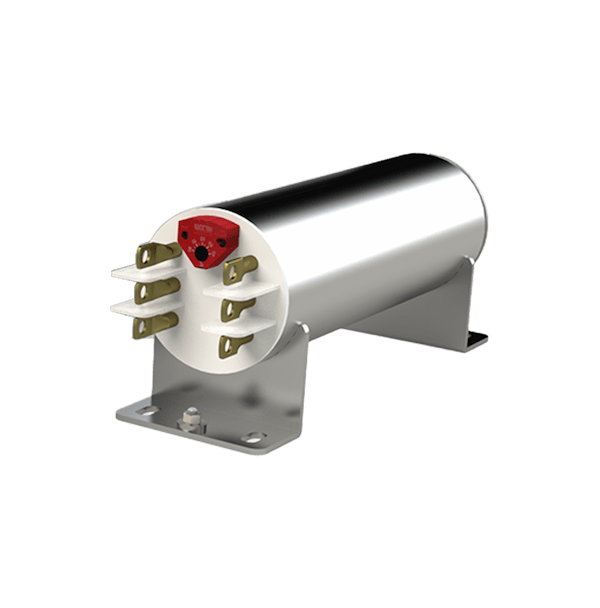

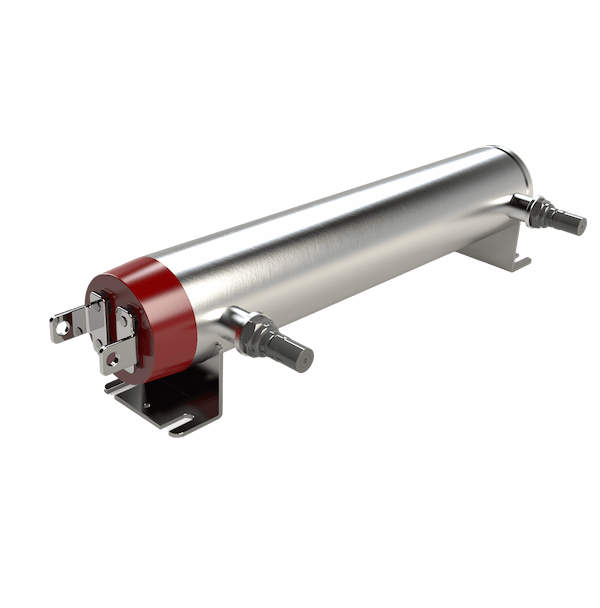

- < 100W

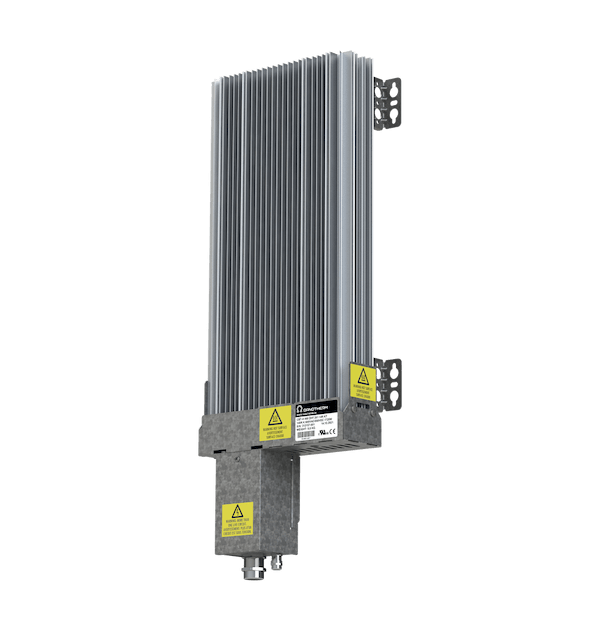

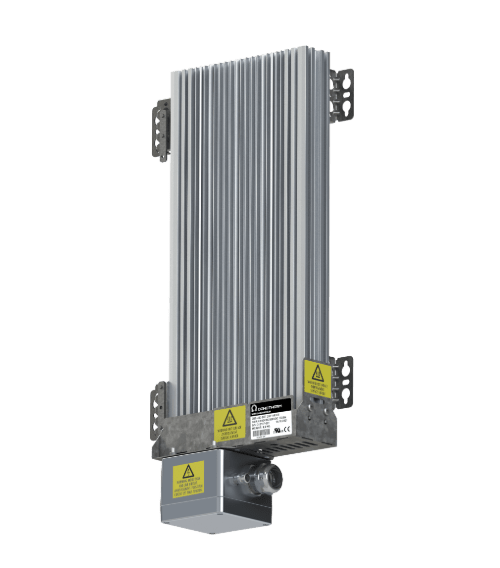

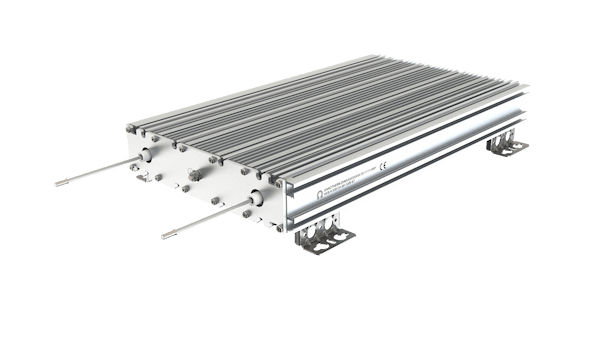

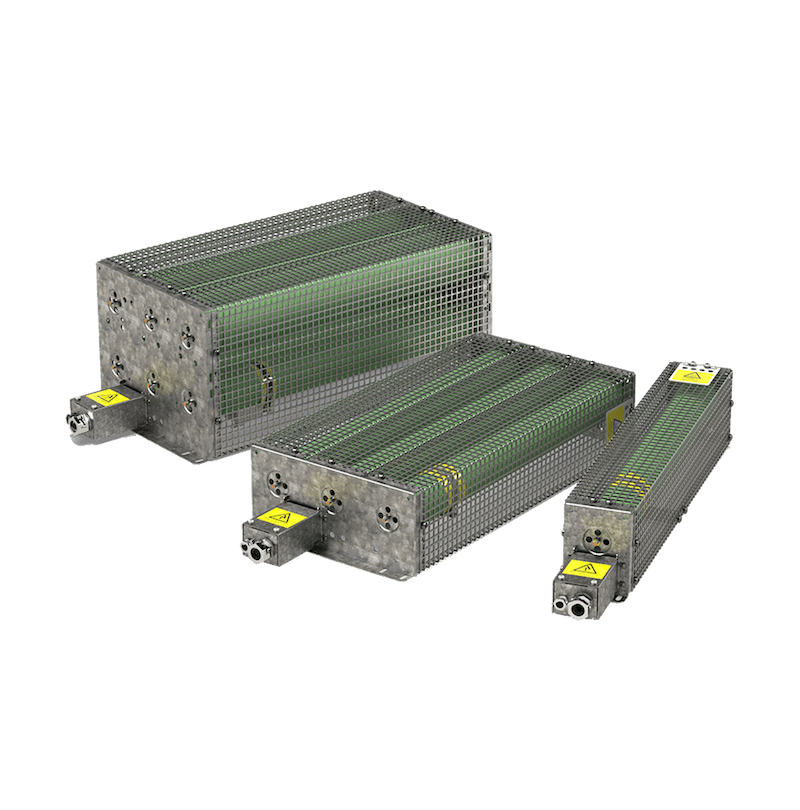

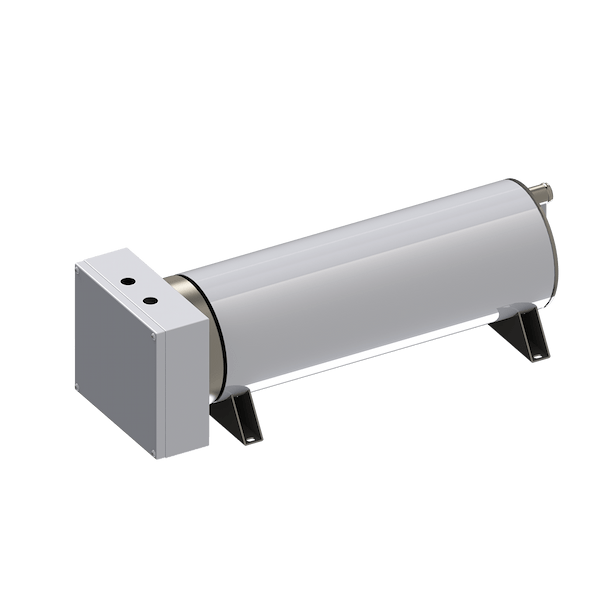

- 100W < P < 1kW

- 1kW < P < 2kW

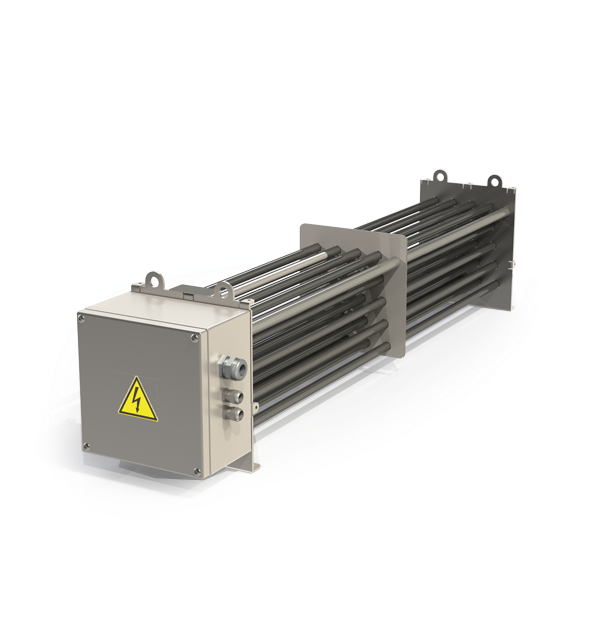

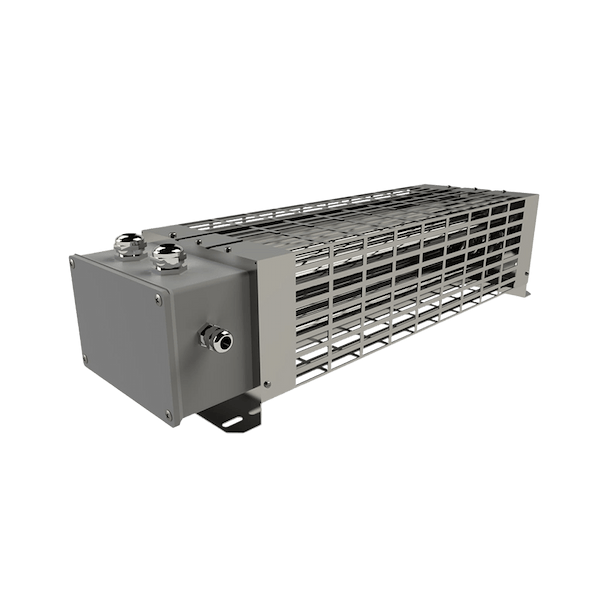

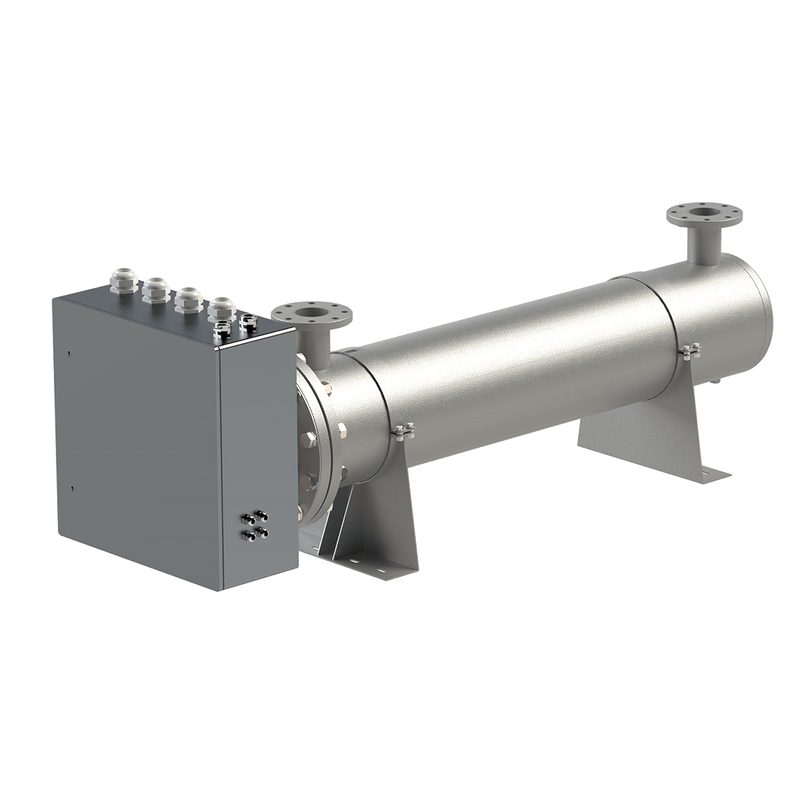

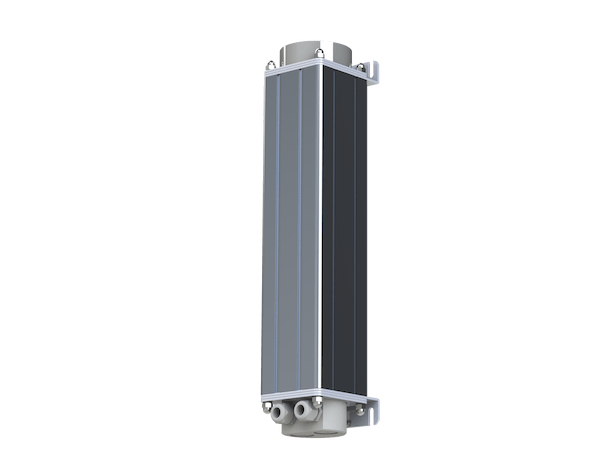

- 2kW < P < 5kW

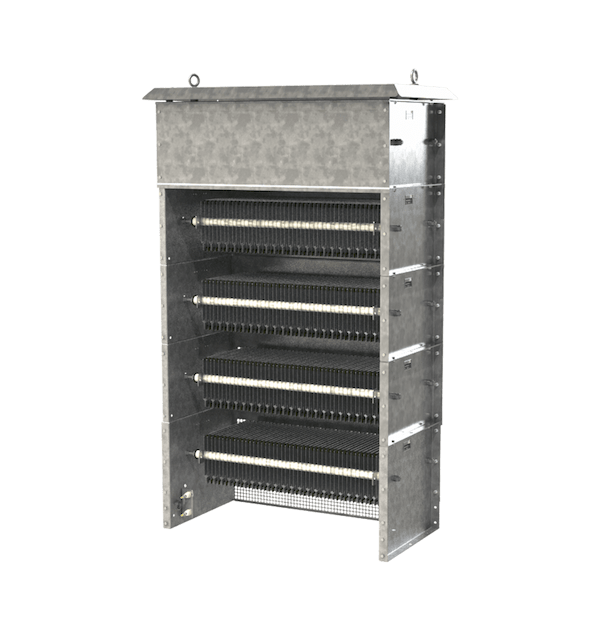

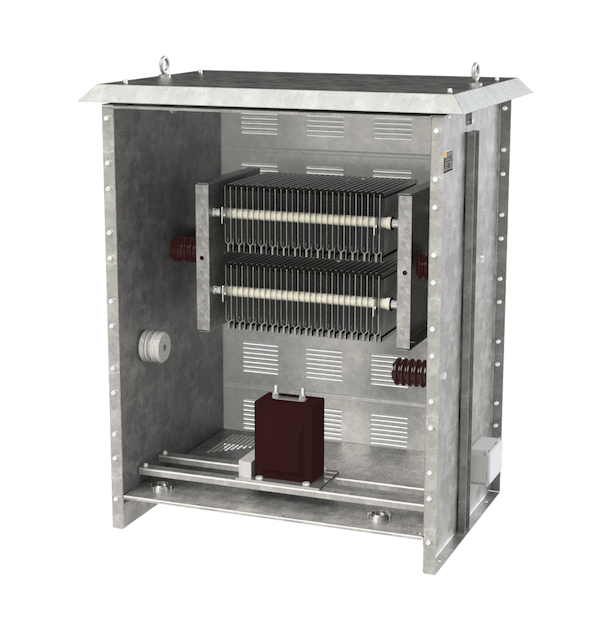

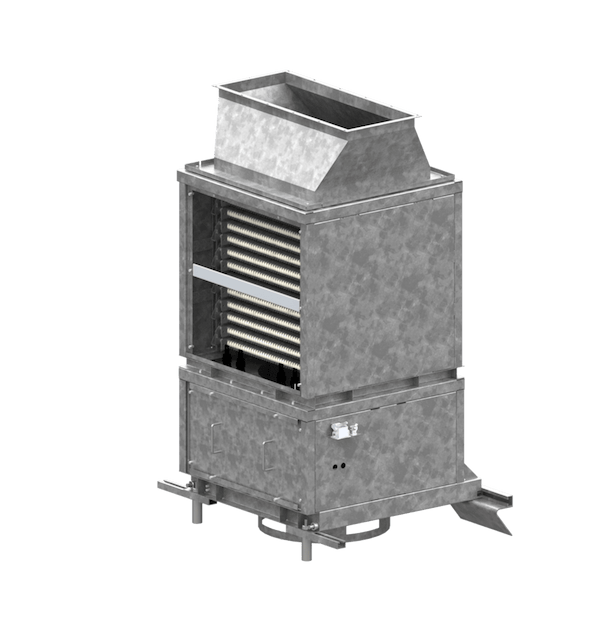

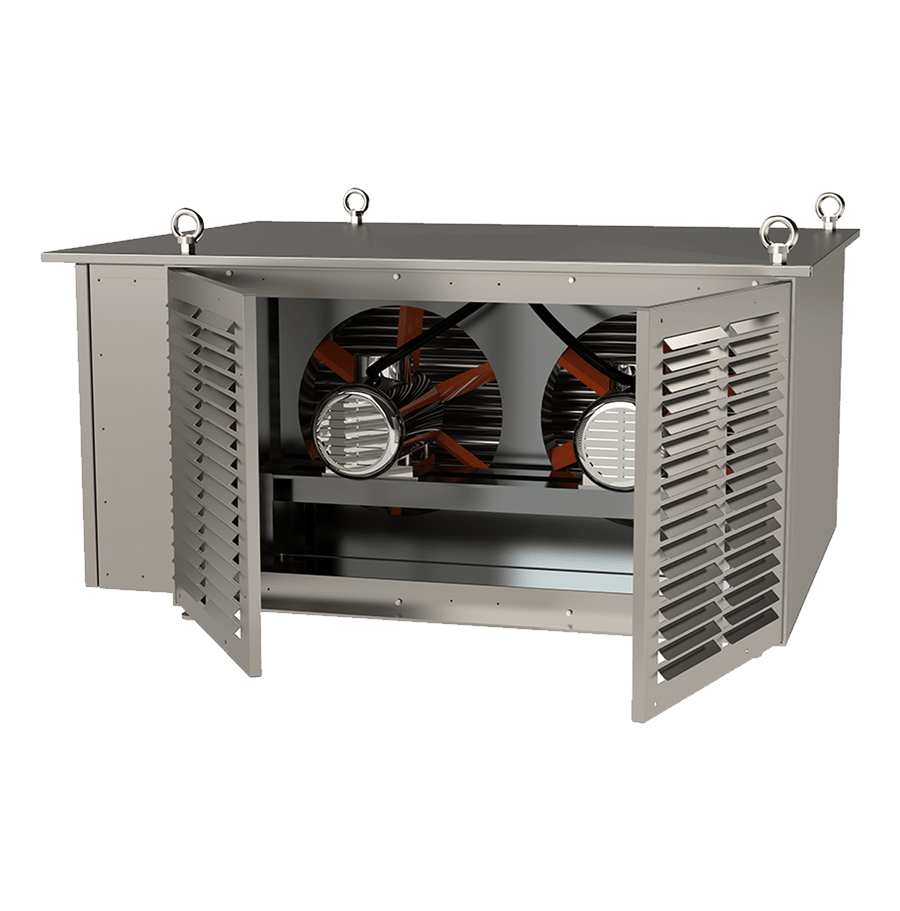

- 5kW < P < 50kW

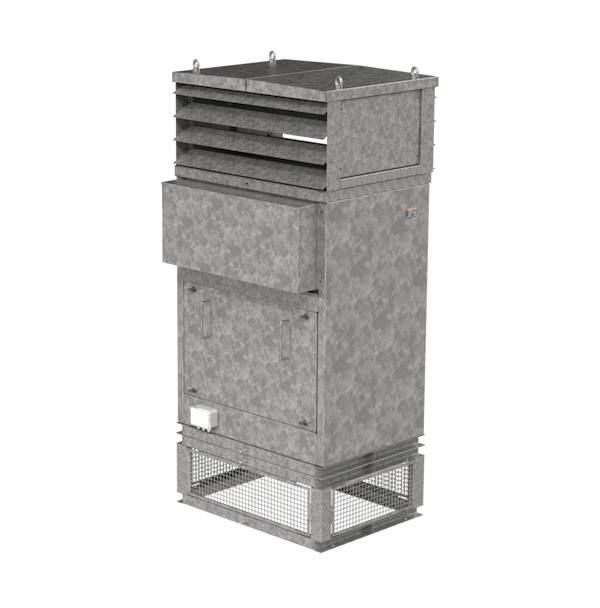

- > 50kW

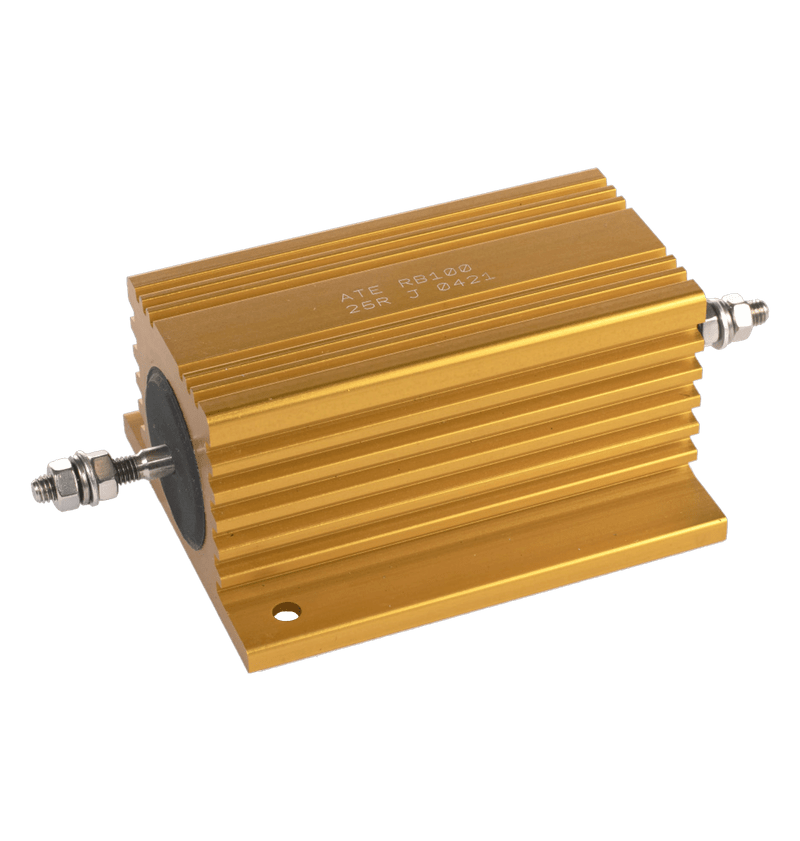

Cooling Method

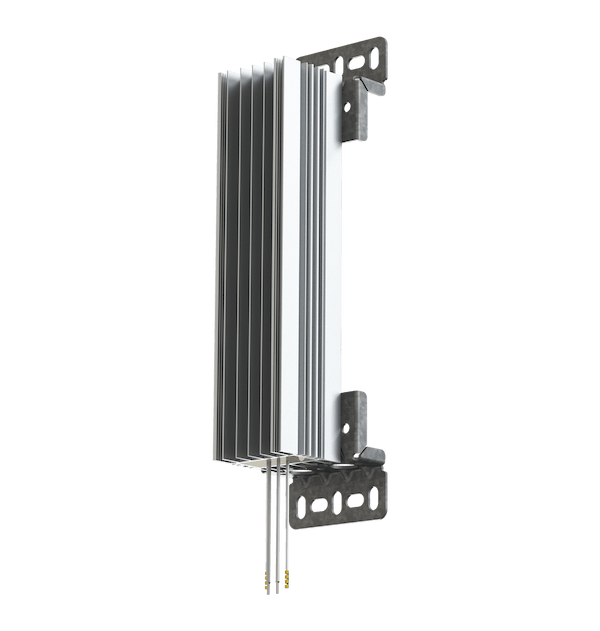

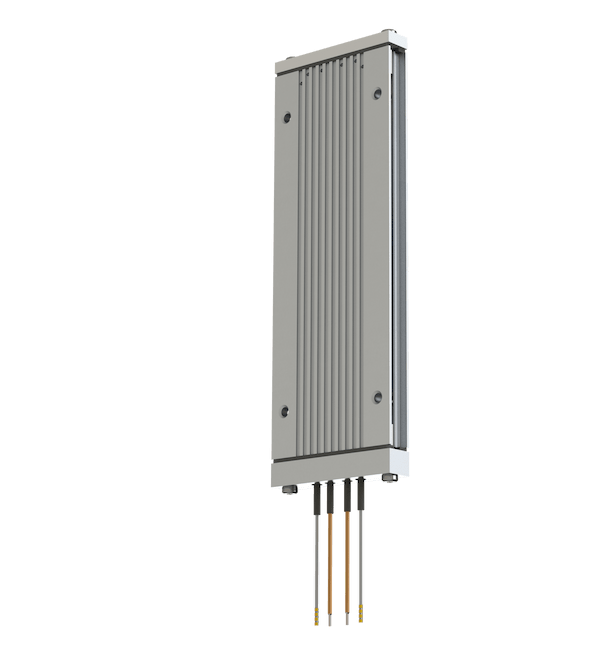

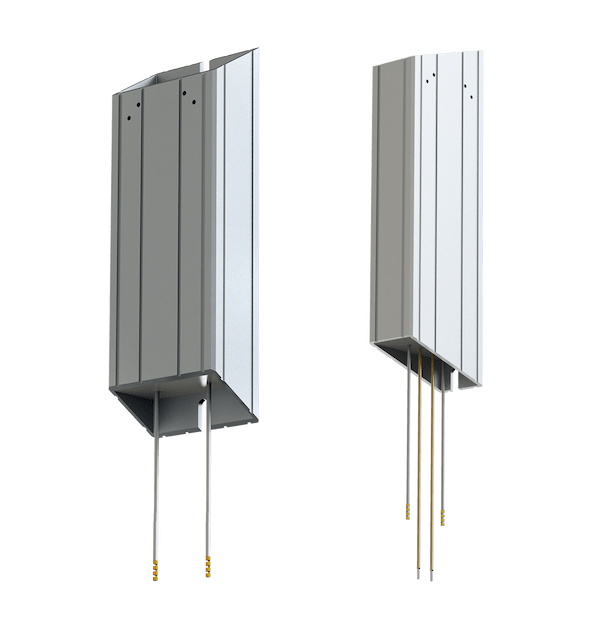

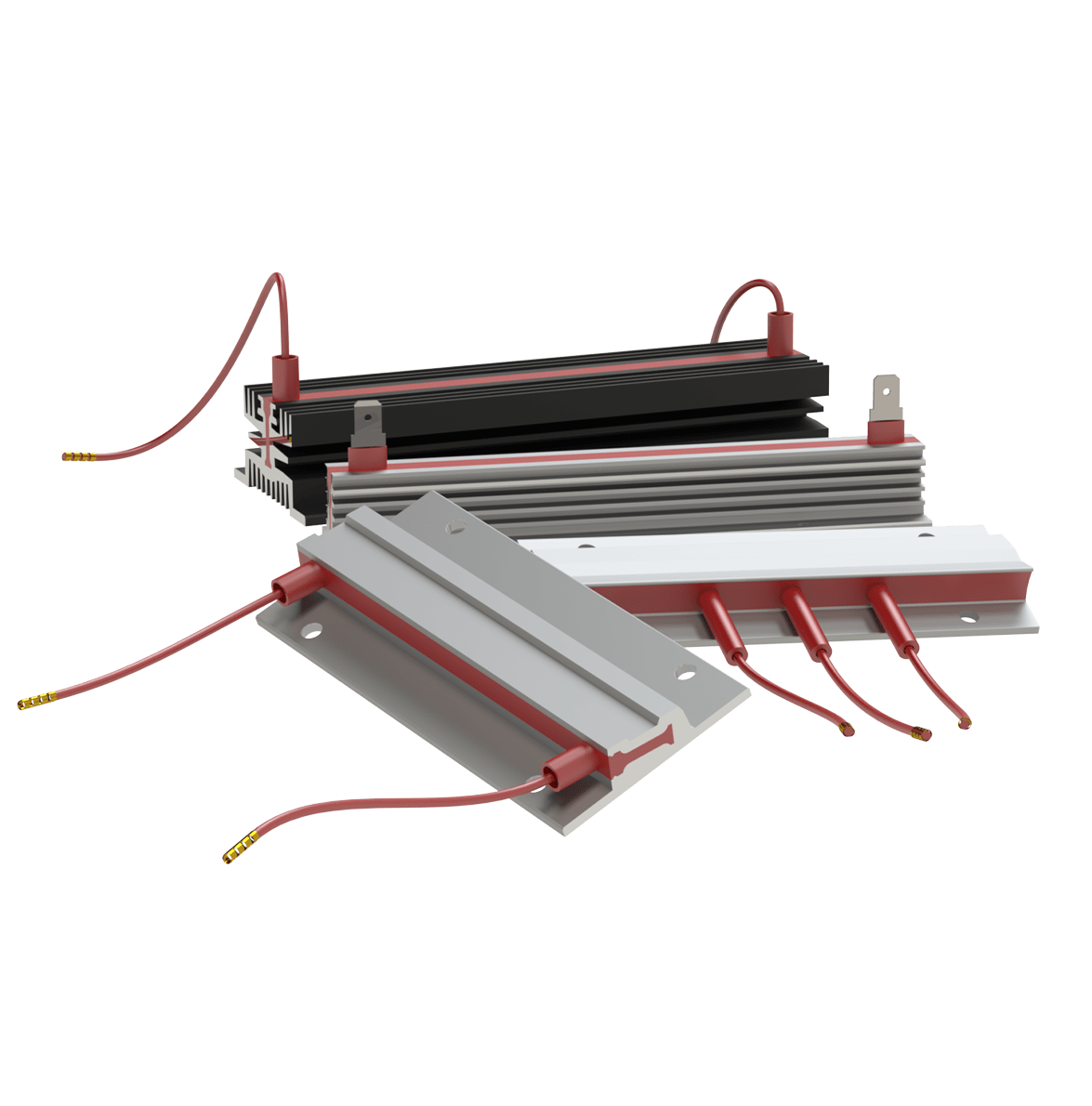

- Convection

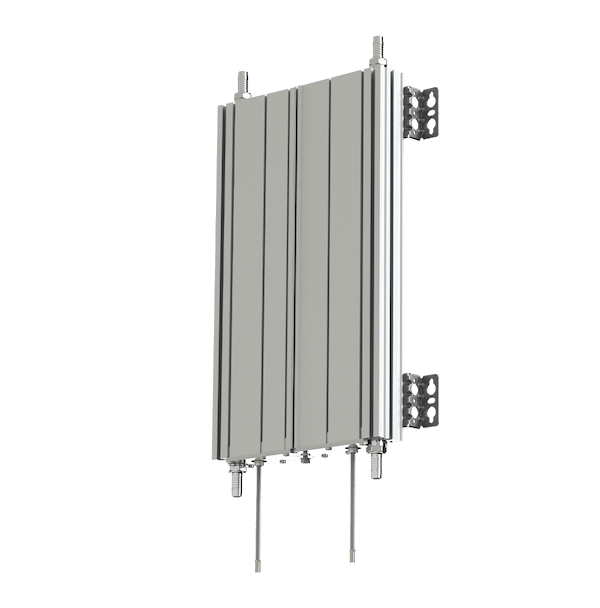

- Liquid

- Ventilator

- Heatsink

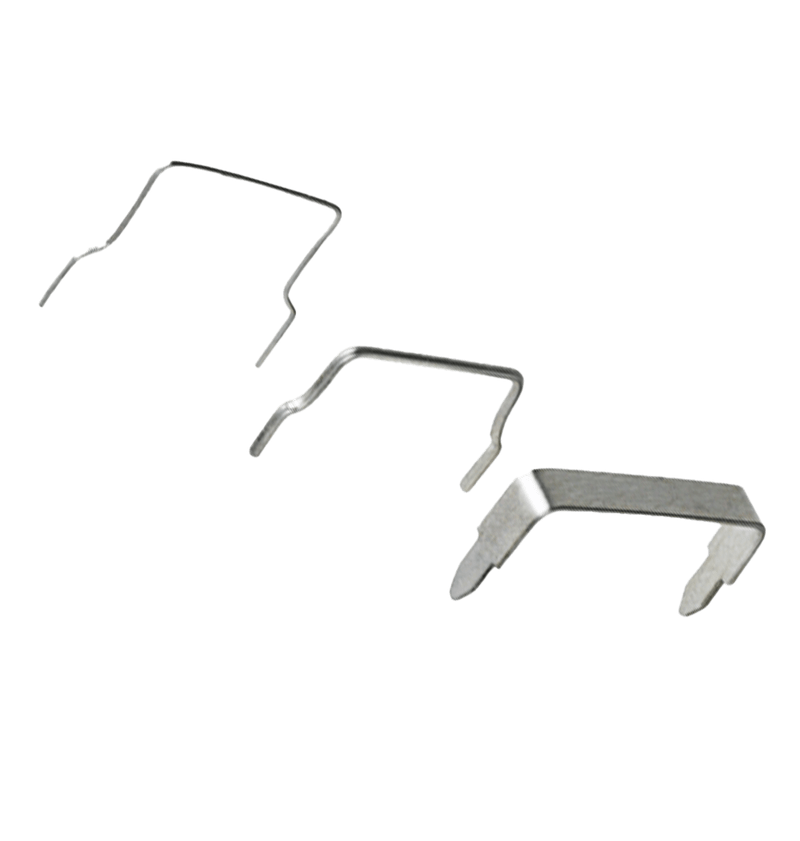

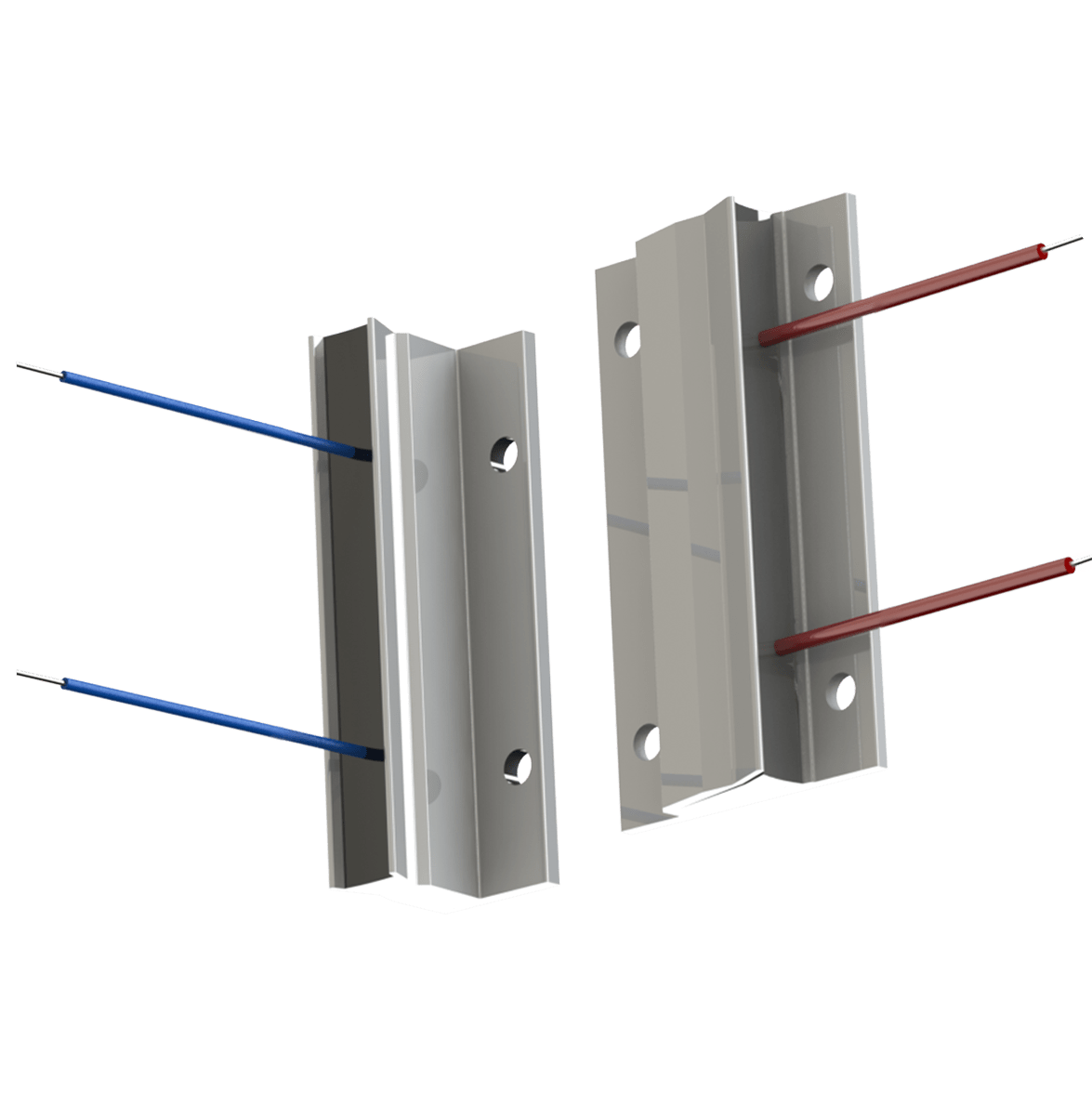

Termination

- Cable

- Box

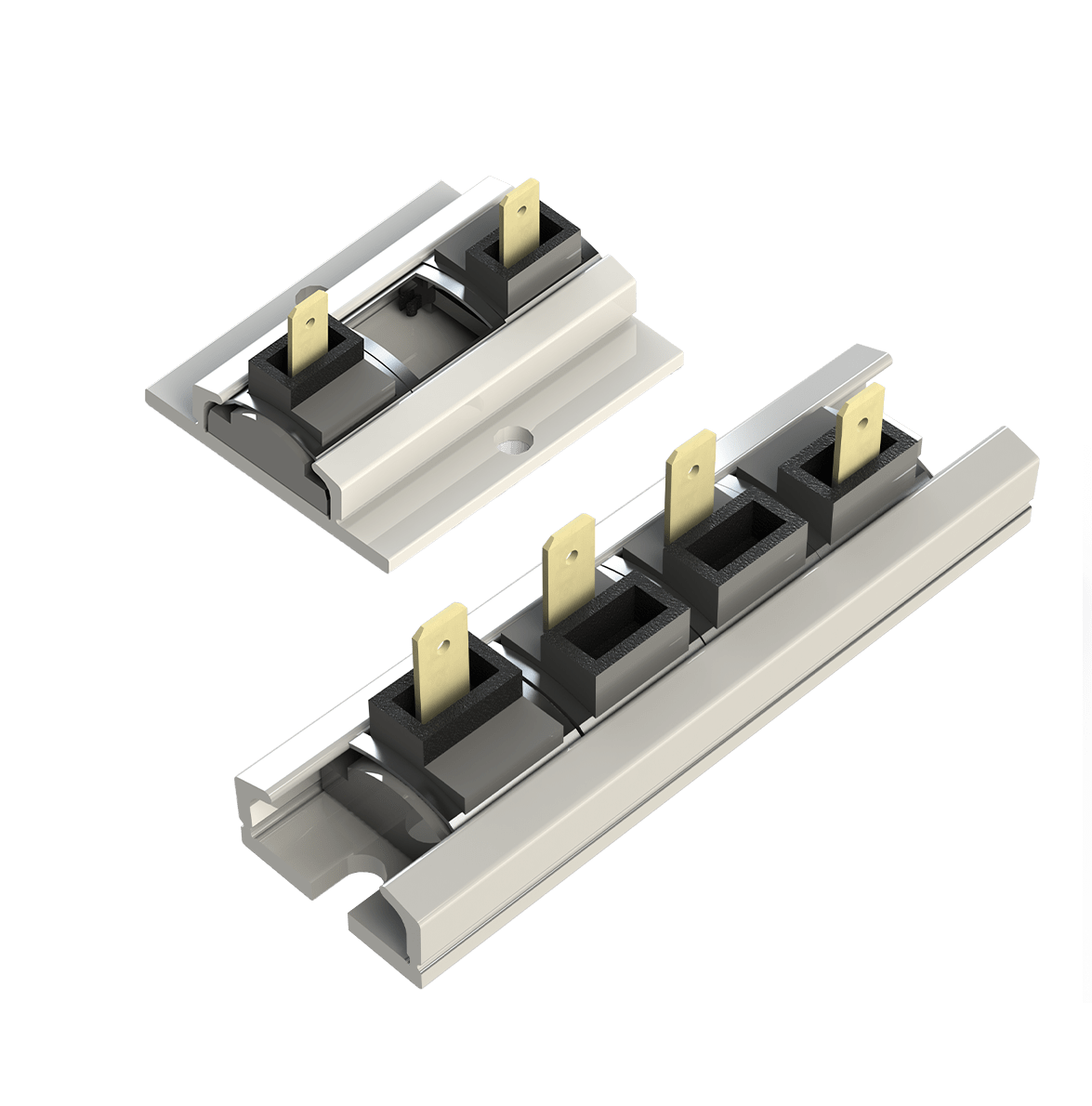

- DIN term

- Stud

- Screw

- Sold

- AMP

- PCB

Protection Class

- IP00

- IP10

- IP13

- IP20

- IP23

- IP44

- IP50

- IP54

- IP60

- IP65

- IP66

UL - Approved

- Yes

- No

Application

- Balance

- Ballast

- Brake

- Charge

- Crowbar

- De-charge

- Dump

- Filter

- Heater

- Loadbank

- NER

- Shunt

- Snubber

FAQ

Frequently asked questions about power resistors