Technical information

Power | 50 kW - 275 kW |

|---|---|

Working voltage | 1000 VAC / 1400 VDC |

Termination | Box |

Protection class | 65, 66 |

Applications

Main applications

- Brake

- Loadbank

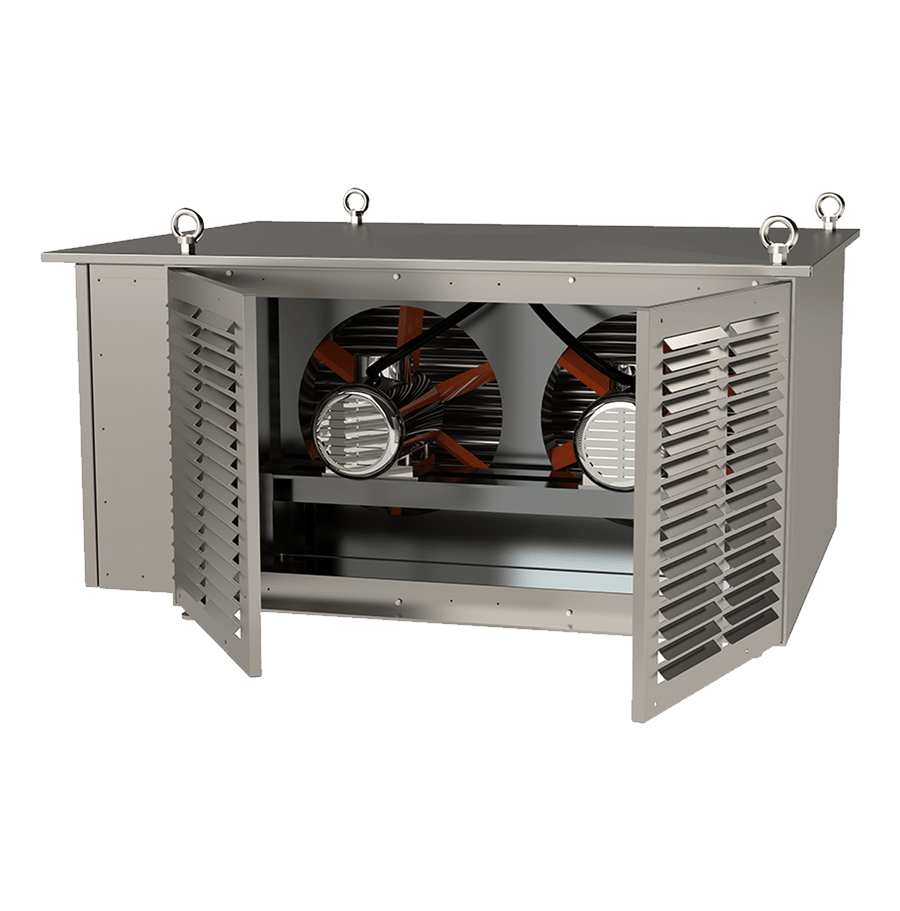

Danotherm TRV resistors are high-power, forced air-cooled resistors. The resistor unit consists of multiple steel tubes welded together into a steel frame and the resistive elements compose of an active wire inside the stainless steel tubes. The tubes contain magnesium oxide with excellent electrical and thermal properties. A stainless steel frame made from AISI 304 or AISI 316L encloses the steel tubes.

Optionally the main resistor elements can be made from AISI 304 / AIS 316L / AISI 321 steel or INCOLOY 800 / 825 alloy that is highly resistant to high temperatures and humid environments.

Nominal power ratings for Danotherm TRV resistors range from 50 to 275 kW, and the working voltages up to 1000 VAC / 1400 VDC. Depending on the resistor, the overload capacity can go up to 7 times the nominal power ratings for a 5-second pulse/120s or 5 times the nominal power rating for a 10-second pulse/120s.

The standard electrical configuration is a single resistor unit. Optionally the resistors can be deployed in star/delta/split topologies. TRV resistors cool via forced air cooling. Depending on the model, the units feature two or four marine-rated ventilators. Heaters for moisture protection come standard on TRV resistors.

Custom resistor designs and Certificates of Conformity or Authenticity are available on request. Danotherm can arrange a Factory Acceptance Test (FAT) at its facility, with or without an accrediting company such as Lloyds, DSV, or RINA being present. Danotherm TRV resistors are IP65/IP66 rated and suitable for harsh environments. Typical applications include braking resistors for cranes and winches for harbor or marine applications.